We guarantee customers get accurate, quickly, on-time, sufficient assistance and services. Paying out close awareness to every item and detail from begin to stop to ensure the accomplishment of every challenge we undertake.

The arrangement in between the two similarly named providers puts them in a very classification by them selves, in accordance with the scientists.

This creates an electrical arc among the electrodes, elevating the temperature of the tool electrode and melting the metal.

A large-frequency laser beam is used in CNC laser machining to slice or etch materials. Contrary to EDM machining, laser machining can machine both metals and non-metals.

Restrict Dimensions: The upper and decreased dimensional limit is described in lieu of defining the needed dimensional size. For illustration, it truly is preset the dimension can fall from the number of 20 mm to 22 mm.

Professional medical technology is starting to become An increasing number of complex. You will discover automated tools and equipment while in the medical industry that may even accomplish surgeries. This equipment needs intricate machining with a micro stage, designed feasible by precision machining.

Making use of these substantial-precision products as part of your production more info process will certainly convey several Gains. High-precision machining is among the most Value-efficient solution, particularly when You merely require a number of to a hundred merchandise.

What exactly is CNC Machining CNC machining can be a manufacturing method, which use programmed Laptop program to regulate factory tools and machinery movement in creating ...

Bredikhin mentioned from the interview the Taiwanese attendees have been his “aged pals.” He reported that he invited them “to drink vodka” and that no small business was discussed in the course of the vacation.

It operates within an organized vogue, turning design and style technical specs into physical parts with extreme precision. Here’s a action-by-step overview of its procedures:

Precision CNC machining tools can be found for several different causes. It can be critical to tighten all clamps appropriately and make sure which the machine properties, like coolant ranges, are suitable throughout this process.

Furthermore, precision grinding will help create shut-tolerance finishes over a completed item by eradicating compact bits of surplus materials.

Excellent Inspection: The moment CNC parts are already machined, they go through an in-depth top quality inspection procedure to make sure every one satisfies style and design specs and tolerances. With higher-precision CNC machines currently available, obtaining steady quality throughout huge production batches can be done.

CNC machines have reworked manufacturing throughout a variety of industries, from automotive and aerospace to medical and Vitality. As we look in the direction of the 2030s, the continued evolution of CNC technology, driven by developments in AI, automation, and materials science, will more increase the capabilities of these machines.

Jurnee Smollett Then & Now!

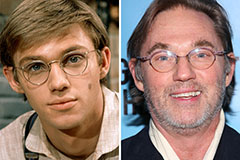

Jurnee Smollett Then & Now! Richard Thomas Then & Now!

Richard Thomas Then & Now! Barbara Eden Then & Now!

Barbara Eden Then & Now! Katey Sagal Then & Now!

Katey Sagal Then & Now! Sarah Michelle Gellar Then & Now!

Sarah Michelle Gellar Then & Now!